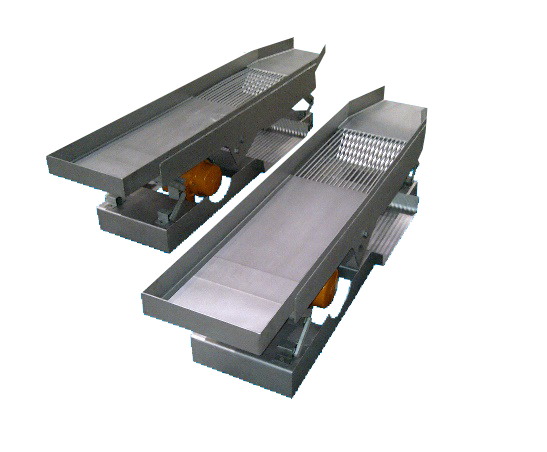

The Mono Drive Screener was designed to provide a simple, rather cheap screening solution, in a small machine. The machine has a high frequency motor (3000 RPM) which is suspended in an oscillating isolator. Therefore it will produce a small stroke and thus nearly no vibration in the support frame. This allows you to place the machine anywhere you like, without worrying about transmitted vibrations. It is available with many options, such as a top cover, mild or stainless steel construction, support structure, Atex etc.

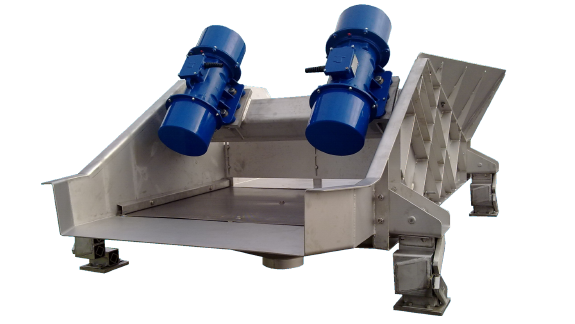

The Dual Drive Screener is based on two contra rotating vibratory motors, which will provide a uni-directional vibrating force. Combined with the 1000 – 1500 RPM this will provide a bigger stroke than the Mono Drive Screener and thus can be used for higher capacities and tougher material. The machine is available in a single or double deck screener, grizzly screener, dewatering screener, with or without top cover, to suit your application where the product needs to separated, rather than sized. It is mounted on oscillating isolators, which will minimise vibration onto structures. It is available with many options, such as a top cover, mild or stainless steel construction, support structure, Atex etc.

The Round Screener is mainly designed for control screening. Removing foreign particles from your product. Standard in a Stainless steel configuration. They are easy to install and maintain without using tools. They are available as standard Sieve, sack tip station or for vacuum processes and in several diameters, 550 – 950 – 1250 and 1550 mm. We also have many options available such as a magnetic separation below the mesh, ultrasonic, top cover, support structure, ATEX etc.

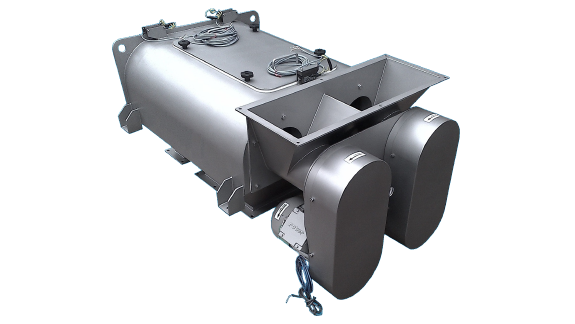

The Centrifugal sifter provides users with an efficient dust tight high throughput non-vibratory sieving machine. The sieving area consists of a mesh cylinder and a paddle blade arrangement revolving within. The product is pushed against the mesh forcing the fine product through. Course product is ejected at the end of the machine. The machine is suitable for high volume sieving, lumpy, sticky and dusty products. It is available with a single or double mesh cylinder.

The labatory Analysers are available in 2 models. The BA200 is suitable for a maximum of 8 sieve trays with a diameter 200/203 mm and has a combined rotating/vertical motion. The digital display allow you to pre-set several parameters like time, amplitude, motion and the quantity of sieve trays. With this you can adjust the analyser to your requirements. The unit is easy to operate. The BA400 is suitable for a maximum of 8 sieve trays with a 400 mm diameter in case you want to analyse larger samples. This model has a separate display and internal memory. This will allow you to memorise several parameters for several products with a maximum of 10.